Benefits of Tailored Chemical Solutions

In today’s fast-evolving industries, one-size-fits-all solutions often fall short of delivering optimal results. This is especially true in chemical manufacturing, where the diverse needs of sectors such as cosmetics, agriculture, and industrial processes demand specialized approaches. Tailored chemical solutions have emerged as a game-changer, offering manufacturers the ability to address unique challenges while maximizing efficiency and performance.

At Unitop Chemicals, we specialize in providing custom chemical formulations, including surfactants and emulsifiers, designed to meet the precise requirements of our clients. In this blog, we explore the key benefits of tailored chemical solutions and why they are a crucial investment for modern businesses.

What Are Tailored Chemical Solutions?

Tailored chemical solutions are customized formulations created to suit specific applications or processes. Unlike off-the-shelf products, these solutions are meticulously designed, keeping in mind factors such as:

- Raw materials compatibility

- Desired product performance

- Environmental considerations

- Cost efficiency

By addressing unique challenges, tailored solutions enable manufacturers to optimize their operations and stay ahead of market demands.

Top Benefits of Tailored Chemical Solutions

- Enhanced Efficiency

Custom chemical formulations are engineered to perform optimally in specific environments or processes. This reduces waste, minimizes downtime, and improves overall efficiency. For example, in industrial cleaning applications, a tailored surfactant blend can achieve superior cleaning power with lower concentrations. - Improved Product Quality

Tailored solutions ensure compatibility with other components, resulting in better product consistency and performance. For cosmetic formulations, this means achieving the perfect texture, stability, and skin feel that consumers demand. - Cost Savings

While customized solutions may have a slightly higher initial cost, their long-term benefits often outweigh the investment. By reducing waste, energy usage, and raw material consumption, tailored formulations save costs across the production cycle. - Sustainability

Eco-friendly practices are no longer optional—they are essential. Tailored solutions can incorporate biodegradable or renewable materials, reducing environmental impact while maintaining efficacy. At Unitop Chemicals, we prioritize sustainability in all our formulations. - Regulatory Compliance

Each industry has its own regulatory requirements. Tailored chemical solutions can be designed to meet local and global standards, ensuring hassle-free compliance and mitigating risks of non-compliance.

Tailored Solutions in Action

At Unitop Chemicals, our expertise lies in creating customized surfactants and emulsifiers that cater to diverse industries, including:

- Personal Care: Developing emulsifiers for skin-friendly cosmetic formulations.

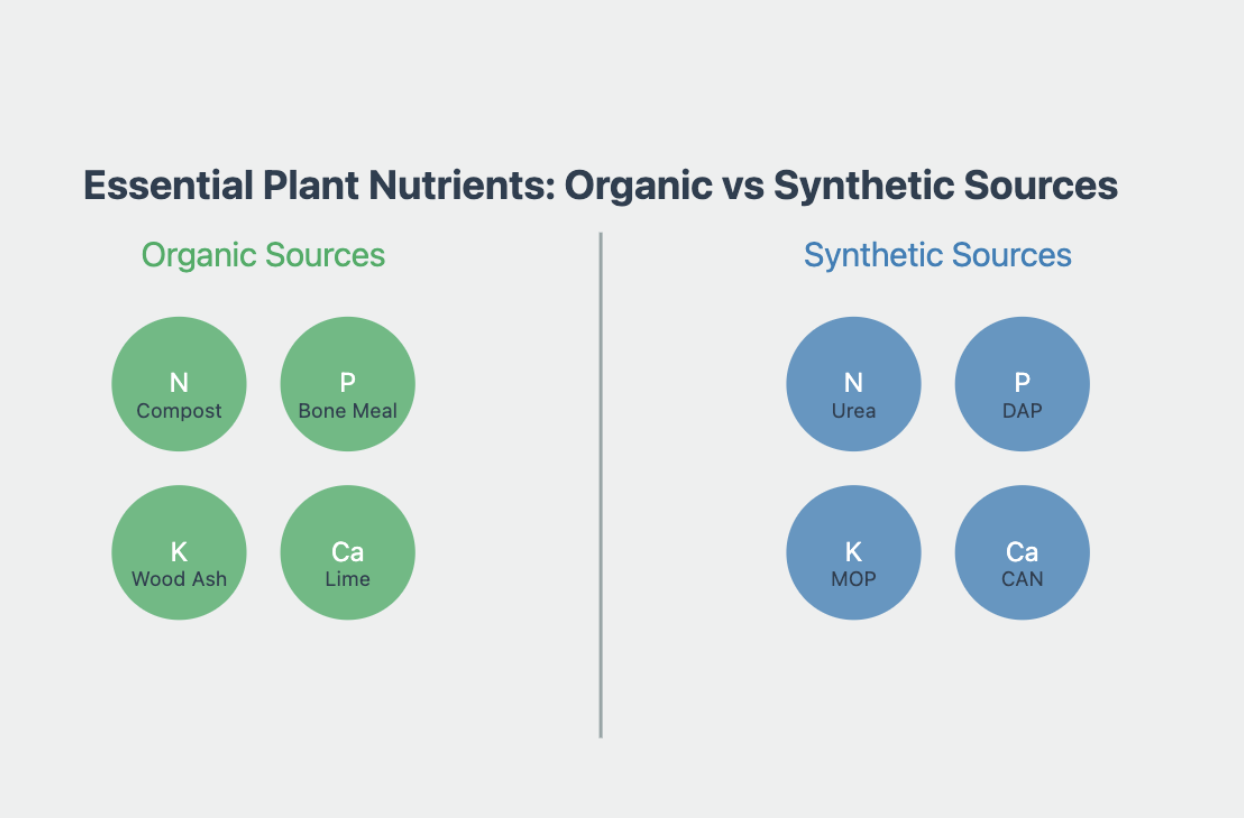

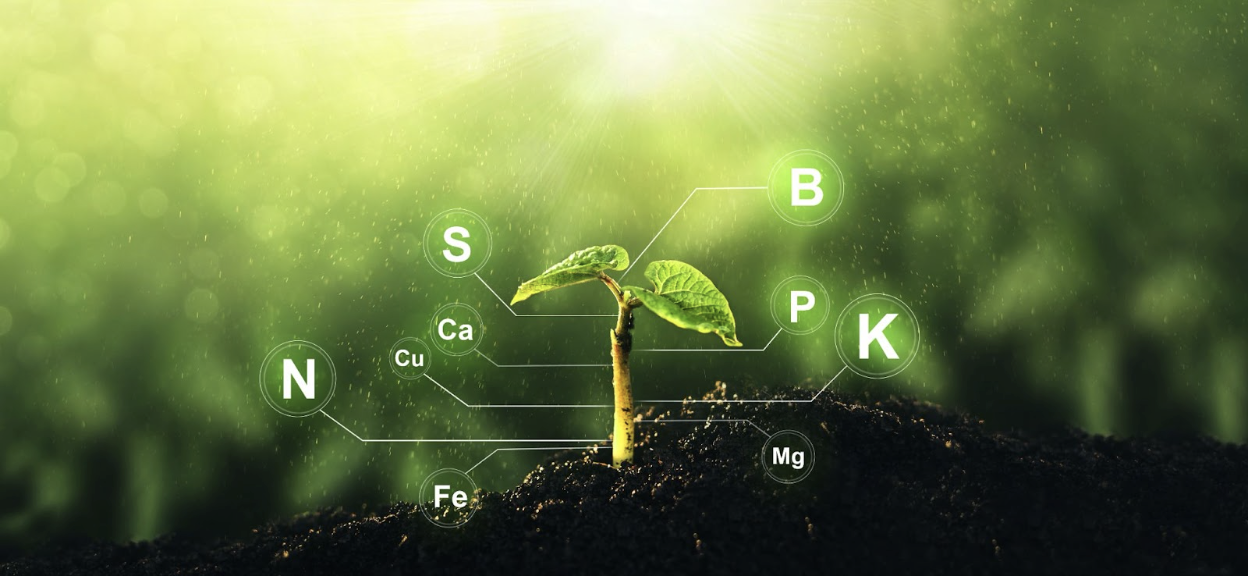

- Agriculture: Crafting adjuvants to enhance the performance of pesticides and fertilizers.

- Industrial Applications: Designing surfactants for effective cleaning and degreasing.

Our collaborative approach ensures that we understand the unique needs of our clients and deliver solutions that exceed their expectations.

Why Choose Unitop Chemicals?

- Expertise: Decades of experience in surfactant and emulsifier production.

- Customization: A proven track record of delivering tailored solutions across industries.

- Sustainability: Commitment to eco-friendly and safe formulations.

- Customer-Centric Approach: We work closely with clients to address specific challenges and provide innovative solutions.

Conclusion

In a competitive market, tailored chemical solutions offer businesses a significant edge. From improving efficiency to ensuring sustainability, customized formulations help manufacturers achieve their goals while adhering to regulatory standards.

Unitop Chemicals is your trusted partner for innovative, high-quality, and sustainable chemical solutions. Contact us today to learn how we can help you unlock the potential of tailored formulations and drive success in your industry.